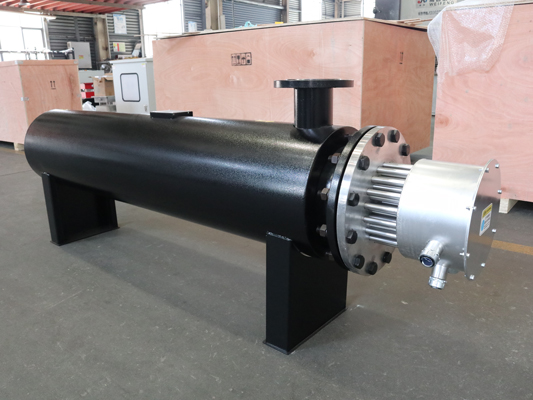

Nkeọkụ eletrik na-ekpo ọkụ nitrogen ọkpọkọ ọkpọkọSistemu bụ ngwaọrụ na-agbanwe ike eletrik ka ọ bụrụ ike ọkụ iji kpoo nitrogen na-eru na pipeline. Nhazi usoro ya kwesịrị iburu n'uche arụmọrụ kpo oku, nchekwa na njikwa akpaaka. Ndị a bụ isi ihe mejupụtara ya na nkọwa zuru ezu:

1,Igwe ọkụ isi modul

1. Igwe ọkụ eletrik

• Isi ihe ndị na-ekpo ọkụ:

Fin ụdị eletriki kpo oku tube: mere nke igwe anaghị agba nchara (dị ka 304 / 316L) ma ọ bụ ihe na-ekpo ọkụ na-ekpo ọkụ, na-agbanye n'elu elu iji mee ka ebe ikpo ọkụ na-ekpo ọkụ ma melite arụmọrụ mgbanwe okpomọkụ. A na-eji waya na-eguzogide (nickel chromium alloy), jupụtara na magnesium oxide powder (MgO) dị ka ihe mkpuchi na ihe na-eme ka ọkụ na-ekpo ọkụ, na-eme ka mkpuchi ọkụ eletrik na nguzogide okpomọkụ dị elu (nkwụsị okpomọkụ nwere ike iru 500 ℃ ma ọ bụ n'elu).

Usoro ntinye:

Nkekpo oku tubesna-ekesa nke ọma n'akụkụ axial direction nke pipeline ma dozie ya na mgbidi dị n'ime ma ọ bụ aka elu nke pipeline site na flanges ma ọ bụ ịgbado ọkụ, na-eme ka kọntaktị zuru ezu na elu kpo oku mgbe nitrogen na-asọ.

Enwere ike ijikọta ọtụtụ tubes kpo oku n'otu n'otu / usoro, na enwere ike nweta iwu ike site na njikwa otu (dị ka ikpo ọkụ nke atọ: obere, ọkara na ike dị elu).

2. Pipeline ahu

Isi pipeline:

Ihe onwunwe: igwe anaghị agba nchara 304/316L (na-eguzogide ikuku nitrogen corrosion), yana 310S ma ọ bụ Inconel alloy dị maka ọnọdụ okpomọkụ dị elu.

Structure: enweghị nkebi ígwè ọkpọkọ ịgbado ọkụ ma ọ bụ flange njikọ, n'ime mgbidi polishing ọgwụgwọ (Ra ≤ 3.2 μ m) iji belata gas eruba eguzogide, ọkpọkọ dayameta mere dị ka nitrogen eruba ọnụego (m ³ / h) na eruba ọsọ (na-atụ aro 5-15m / s), na nnabata GB / T 189814 ma ọ bụ ASME ọkọlọtọ B.

• oyi akwa mkpuchi:

Kechie elu mpụta na ajị nkume ma ọ bụ aluminom silicate fiber, na a ọkpụrụkpụ nke 50-100mm, na-ekpuchi ya na igwe anaghị agba nchara efere iji belata okpomọkụ ọnwụ (n'elu okpomọkụ ≤ 50 ℃).

2,Usoro njikwa

1. Igwe njikwa okpomọkụ

• ihe mmetụta:

Ihe nlere okpomọkụ: Pt100 thermistor (nkenke ± 0.1 ℃) ma ọ bụ K-ụdị thermocouple (oke okpomọkụ na-eguzogide ≥ 1000 ℃), arụnyere na ntinye na ntinye nke pipeline na n'etiti etiti ikpo ọkụ, iji nyochaa okpomọkụ n'oge.

Ihe mmetụta ọsọ/nrụgide: vortex flowmeter, thermal mass flowmeter (ntụgharị nha), onye na-ebugharị nrụgide (nrụgide nha), ejiri gbakọọ ike ọkụ ọkụ.

• Onye njikwa:

Sistemu PLC ma ọ bụ DCS: PID algọridim jikọtara ọnụ, na-agbanwe ike kpo oku na-akpaghị aka dabere na okpomoku setịpụrụ (dịka site na thyristor power regulator ma ọ bụ SSR siri ike relay steeti), na-akwado nleba anya anya na ndekọ data.

2. Igwe njikwa eletriki

• Sistemu ike:

◦ Ntinye ike ntinye: AC 380V/220V,50Hz,Hazie ihe mgbawa sekit na ihe nchekwa ọgbaghara iji kwado ọkụ n'usoro n'usoro atọ.

Njikwa ike: Mgbasa ozi steeti siri ike (SSR) ma ọ bụ onye na-achịkwa ike, mgbanwe na-enweghị kọntaktị, ọsọ nzaghachi ngwa ngwa, ogologo ndụ.

• Ngwa nchekwa nchekwa:

Nchedo oke okpomọkụ: Ejiri ya na igwe ọkụ ọkụ bimetallic arụnyere arụnyere ma ọ bụ ngbanwe okpomọkụ, mgbe ọ̀tụ̀tụ̀ ọkụ a tụrụ atụ̀ gafere uru echere (dị ka 20 ℃ dị elu karịa okpomọkụ a na-achọsi ike), a na-ebipụ ọkụ ọkụ n'ike ma kpalite mkpu.

Nchedo sekit na-agafe agafe / dị mkpụmkpụ: ihe ngbanwe dị ugbu a + ihe na-agbaji okirikiri iji gbochie mmebi sekit na-akpata site na mmejọ tube kpo oku.

Nchedo nrụgide: A na-ejikọta ngbanwe nrụgide na-emechi ka ọ ghara igbochi pipeline overpressure (kpaliri mgbe ọ karịrị 1.1 ugboro nrụgide nhazi).

Ọrụ njikọta: Ejikọtara ya na isi iyi nitrogen, amachibidoro ikpo ọkụ mgbe enweghị ikuku gas iji zere ọkụ ọkụ.

3,Ihe inyeaka

1. Jikọọ na wụnye components

Mbubata na mbupụ flanges: RF flat flanges (PN10/PN16) na-eji, na otu ihe dị ka pipeline, na sealing gasket bụ a metal ọbọp gasket ma ọ bụ PTFE gasket.

• Bracket na idozi akụkụ: Carbon ígwè galvanized ma ọ bụ igwe anaghị agba nchara, na-akwado nrụnye kwụ ọtọ / kwụ ọtọ, na oghere e mere dịka dayameta ọkpọkọ na ibu ibu (dị ka DN50 pipeline bracket spacing ≤ 3m).

2. Nleba anya nyocha na mmezi

Okpomọkụ/ntụgharị nha ihu: Reserve G1/2 "ma ọ bụ NPT1/2" threaded interfaces na ntinye na ntinye nke pipeline maka mfe disassembly na calibration nke sensọ.

• Mwepu mkpofu: A na-etinye valvụ mgbapụta DN20 na ala nke pipeline maka mwepu nke mmiri na-ekpo ọkụ ma ọ bụ adịghị ọcha mgbe niile (ọ bụrụ na nitrogen nwere oke mmiri).

• oghere nyocha: Ogologo pipeline ma ọ bụ ihe mgbagwoju anya na-eji flanges nyocha oghere ngwa ngwa maka ngbanwe dị mfe nke ọkpọkọ kpo oku na nhicha nke mgbidi dị n'ime.

4,Nchekwa na ihe mgbawa chepụta (ọ bụrụ na achọrọ ya)

Ngosipụta ihe mgbawa: Ọ bụrụ na ejiri ya na gburugburu ọkụ na mgbawa (dị ka ụlọ ọrụ petrochemical), sistemụ ahụ ga-agbaso ụkpụrụ mgbawa Ex d IICT6, tube kpo oku kwesịrị ịbụ ihe mgbawa (ya na asambodo mgbawa maka igbe njikọ), na akụrụngwa eletrik kwesịrị itinye n'ime igbe njikwa ihe mgbawa.

Nchedo ala: Sistemu niile dabere na ntụkwasị obi (nguzogide ala ≤ 4 Ω) iji gbochie mkpokọta ọkụ eletrik kwụ ọtọ na ihe egwu ịwepu.

5,Ngwa a na-ahụkarị

Industrylọ ọrụ kemịkalụ: nitrogen purging, reactor preheating, ihicha usoro kpo oku.

Ụlọ ọrụ eletrọnịkị: Igwe ọkụ nitrogen dị ọcha dị elu na nrụpụta semiconductor (chọrọ polishing mgbidi dị n'ime iji zere mmetọ).

Ọgwụ Metallurgy/Okpomọkụ: Ọkụ na-abanye n'ime ọkụ, mgbachi igwe na kpo oku ikuku na-echebe.

chịkọta

Nkeọkụ eletrik na-ekpo ọkụ nitrogen ọkpọkọ ọkpọkọSistemu gbadoro ụkwụ n'akụkụ ihe ndị na-ekpo ọkụ eletrik ma na-enweta oke okpomọkụ site na njikwa ọgụgụ isi. Nhazi ya kwesịrị ịhazi nrụnye ọkụ, nchekwa, na njikarịcha ike mmiri, na-eme ka ọ dabara maka ọnọdụ ụlọ ọrụ na-achọ okpomọkụ, ịdị ọcha, na mgbochi mgbawa. Mgbe ị na-emepụta ihe, ihe, nhazi ike, na atụmatụ nchịkwa kwesịrị ịhọrọ dabere na ọnọdụ ọrụ kpọmkwem (ọnụego mmiri, okpomọkụ, nrụgide, gburugburu ebe obibi) iji hụ na arụ ọrụ kwụsiri ike ogologo oge.

Ọ bụrụ na ịchọrọ ịmatakwu gbasara ngwaahịa anyị, bikokpọtụrụ anyị!

Oge nzipu: Eprel-10-2025